Page 169 - HUDCO DESIGN AWARDS 2023-24

P. 169

DESIGNED FOR THE INDIAN URBAN WASTE

The annual processing of about 100000 tons of MSW in the plant generates 43.75 million units of green power and

reduces the reliance on fossil fuels for electricity production, aligning with climate change mitigation strategies. Moreover, by

processing non-recyclable plastics within the MSW, approximately 22000 tons of plastic pollution that could enter the ocean,

is prevented. Also, it is estimated to reduce approximately 36,054 tons of CO2 equivalent emissions annually, curbing the

release of greenhouse gases that contribute to global warming.

The patented technology developed for the conversion of municipal solid wastes to usable forms of clean energy and other

green by-products has been designed for the Indian urban context and customised for cities waste characterization in terms

of type and quantum of waste generated. Also, it involves absolutely no human interface during the entire process from start

to finish. Additional value chains created in Waste-to-Energy sector include producing BioCNG from organic MSW content,

recovering recyclable plastic from heterogeneous MSW, exploring green chemical production from specific MSW components,

co-firing eligible industrial waste, and setting up facilities to convert fly ash into finished products such as green construction

blocks and pavers.

Conventional waste disposal practices need large tracts of land to dump municipal solid waste. As per estimates, 50 acres

of land can be conserved, considering average 10 m height of dumpsite for 20 years, thereby avoiding the establishment of

large dumpsites.

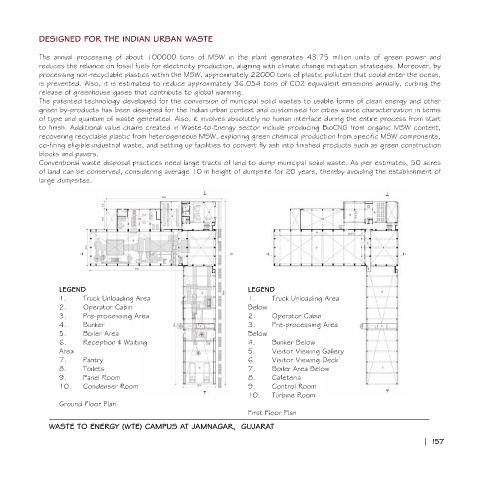

LEGEND LEGEND

1. Truck Unloading Area 1. Truck Unloading Area

2. Operator Cabin Below

3. Pre-processing Area 2. Operator Cabin

4. Bunker 3. Pre-processing Area

5. Boiler Area Below

6. Reception & Waiting 4. Bunker Below

Area 5. Visitor Viewing Gallery

7. Pantry 6. Visitor Viewing Deck

8. Toilets 7. Boiler Area Below

9. Panel Room 8. Cafeteria

10. Condenser Room 9. Control Room

10. Turbine Room

Ground Floor Plan

First Floor Plan

WASTE TO ENERGY (WTE) CAMPUS AT JAMNAGAR, GUJARAT

| 157