Page 40 - HUDCO-SHELTER-APR21

P. 40

THEME PAPER

Table No 2: Light House Project 0 Rajkot (Gujarat)2

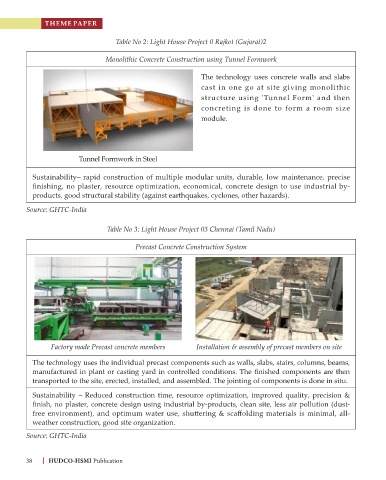

Monolithic Concrete Construction using Tunnel Formwork

The technology uses concrete walls and slabs

cast in one go at site giving monolithic

structure using 'Tunnel Form' and then

concreting is done to form a room size

module.

Tunnel Formwork in Steel

Sustainability– rapid construction of multiple modular units, durable, low maintenance, precise

finishing, no plaster, resource optimization, economical, concrete design to use industrial by-

products, good structural stability (against earthquakes, cyclones, other hazards).

Source: GHTC-India

Table No 3: Light House Project 03 Chennai (Tamil Nadu)

Precast Concrete Construction System

Factory made Precast concrete members Installation & assembly of precast members on site

The technology uses the individual precast components such as walls, slabs, stairs, columns, beams,

manufactured in plant or casting yard in controlled conditions. The finished components are then

transported to the site, erected, installed, and assembled. The jointing of components is done in situ.

Sustainability – Reduced construction time, resource optimization, improved quality, precision &

finish, no plaster, concrete design using industrial by-products, clean site, less air pollution (dust-

free environment), and optimum water use, shu ering & scaffolding materials is minimal, all-

weather construction, good site organization.

Source: GHTC-India

38 HUDCO-HSMI Publication