Page 28 - HUDCO-SHELTER-April22

P. 28

THEME PAPER

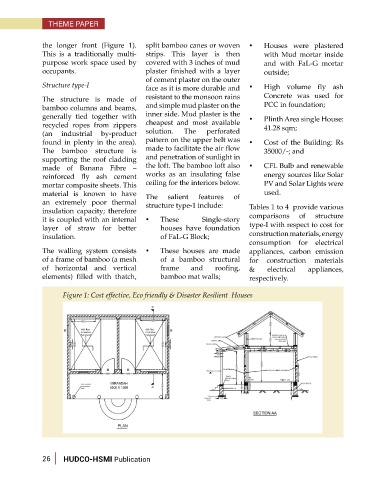

the longer front (Figure 1). split bamboo canes or woven Houses were plastered

This is a traditionally multi- strips. This layer is then with Mud mortar inside

purpose work space used by covered with 3 inches of mud and with FaL-G mortar

occupants. plaster finished with a layer outside;

of cement plaster on the outer

Structure type-I face as it is more durable and High volume fly ash

The structure is made of resistant to the monsoon rains Concrete was used for

bamboo columns and beams, and simple mud plaster on the PCC in foundation;

generally tied together with inner side. Mud plaster is the Plinth Area single House:

recycled ropes from zippers cheapest and most available 41.28 sqm;

(an industrial by-product solution. The perforated

found in plenty in the area). pattern on the upper belt was Cost of the Building: Rs

The bamboo structure is made to facilitate the air flow 35000/-; and

supporting the roof cladding and penetration of sunlight in

made of Banana Fibre – the loft. The bamboo loft also CFL Bulb and renewable

reinforced fly ash cement works as an insulating false energy sources like Solar

mortar composite sheets. This ceiling for the interiors below. PV and Solar Lights were

material is known to have The salient features of used.

an extremely poor thermal structure type-1 include:

insulation capacity; therefore Tables 1 to 4 provide various

it is coupled with an internal These Single-story comparisons of structure

layer of straw for better houses have foundation type-I with respect to cost for

insulation. of FaL-G Block; construction materials, energy

consumption for electrical

The walling system consists These houses are made appliances, carbon emission

of a frame of bamboo (a mesh of a bamboo structural for construction materials

of horizontal and vertical frame and roofing, & electrical appliances,

elements) filled with thatch, bamboo mat walls; respectively.

Figure 1: Cost effective, Eco friendly & Disaster Resilient Houses

26 HUDCO-HSMI Publication